Counter Rotation Wet Drum Magnetic Separator for Rougher Separation Stage

Quality magnet provides stable performance.

The material of the tank is 304 stainless steel with thickness 4-6mm. Submerged arc welding or CO2 gas protecting welding will be used for all welding seams. Natural rubber or PU liners are required for high wear area. So it will improve the wearable performance and extend the service life of the tank.

The tank and supporting frame are modular designs. The two supporting ends of the tank can be adjusted around within certain range. Tank cleaning mechanism is designed on two sides of the tank, so it helps to clean the silt inside the tank.

We use the spray bar with nozzles. Better discharging results, water save, easy to clean and no slurry jam.

The material of the supporting frame is mild steel. Hot-dip galvanized surface treatment on the mild steel will protect the frame in strong corrosive site.

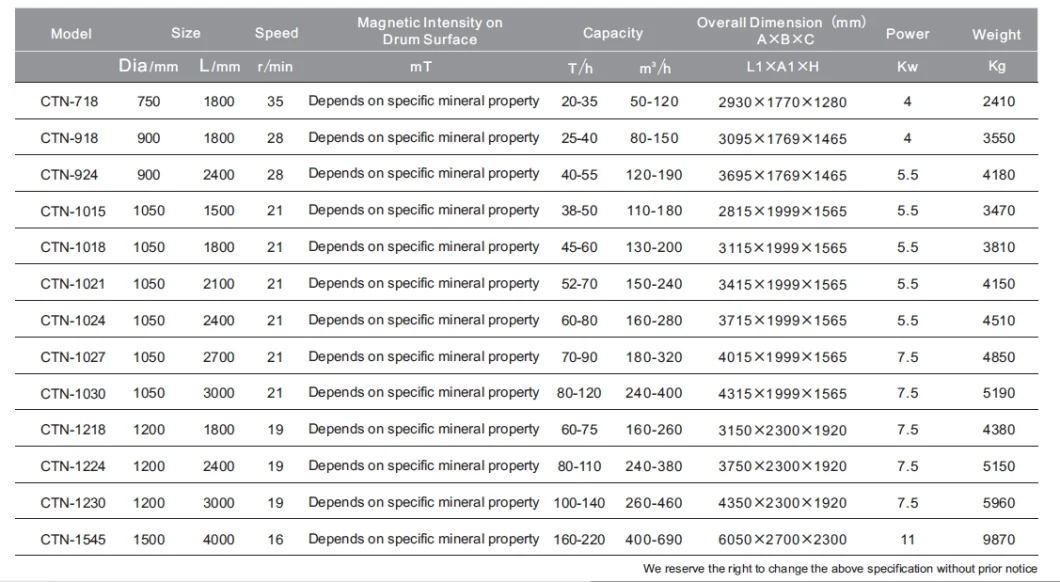

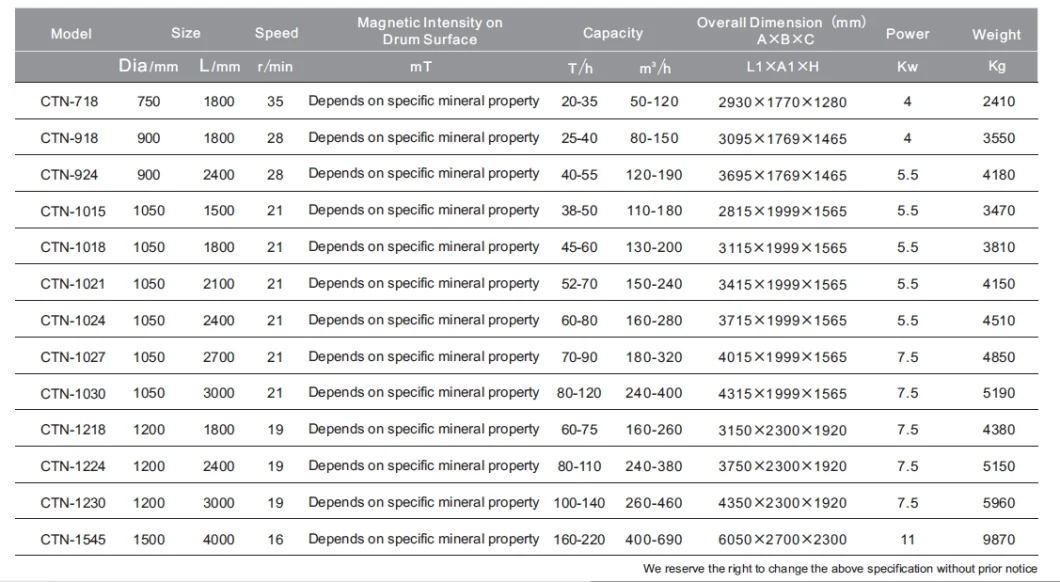

Technical Parameters

Application

LONGi 's Service Guarantee

One on One Service

LONGi Laboratory introduction

LONGi Laboratory was established in 2006. It is a comprehensive mineral processing laboratory with magnetic separation gravity separation, flotation and X-ray separation. It is an important part of the magnetic separation engineering technology research center which is approved by CMIF (China Machinery Industry Federation).The laboratory covers an area of more than 4000 square meters, with a complete single magnetic separation testing machines and with a combined in any combination of magnetic separation, gravity separation, and flotation separation testing lines.

The LONGi mineral processing laboratory can conduct mineral processing research experiments, confirmatory experiments and process flow sheet design experiments, analyze the properties of the ore in combination with the experimental data, and provide optional experimental reports, and provide process flow sheet and the basis for equipment model selection.

The LONGi mineral processing Laboratory can provide mineral processing experiments and main mineral elements analysis services for domestic and foreign beneficiation plants and scientific research institutes. It also undertakes the internship tasks of undergraduate and graduate students majoring in mineral processing at China University of Mines, Northeastern University and other universities. It is a test base for high-tech mineral processing equipment and the cradle of technical talents in mineral processing in northern China.

Packing, Storage, and Transportation

Longi has plenty of cases and much experience for delivery of the heavy equipment. Some of the equipment is disassembled into pieces during shipment. The key parts like motor will be fully sealed during transportation.

The magnetic separator is used for recovery of iron ore processing. It effectively increases Fe content and decreases the silica and other waste. The counter rotation wet drum magnetic separator is also suitable for the dense media recovery.

Product FeaturesQuality magnet provides stable performance.

Shaft is well protected from magnet system for safe running.

Sludge discharge on both ends of tank allows easy cleaning.

Technical advantage

The material of the tank is 304 stainless steel with thickness 4-6mm. Submerged arc welding or CO2 gas protecting welding will be used for all welding seams. Natural rubber or PU liners are required for high wear area. So it will improve the wearable performance and extend the service life of the tank.The tank and supporting frame are modular designs. The two supporting ends of the tank can be adjusted around within certain range. Tank cleaning mechanism is designed on two sides of the tank, so it helps to clean the silt inside the tank.

We use the spray bar with nozzles. Better discharging results, water save, easy to clean and no slurry jam.

The material of the supporting frame is mild steel. Hot-dip galvanized surface treatment on the mild steel will protect the frame in strong corrosive site.

Technical Parameters

Application

The counter rotation wet drum magnetic separator is widely used for rougher stage of iron ore processing. With the large capacity and stable operation, the end users love this equipment. The counter rotation wet drum magnetic separator is also used in coal washing plant in order to recycle the dense media.

The Customer Site Case

LONGi 's Service Guarantee

One on One Service

LONGi's in house laboratory is well known for providing professional and accurate sample testing for a wide variety of clients in both the mineral and recycling industries. Based on the lab test results and often a necessary site survey our experienced engineers are proud to be able to offer the best solution available every time we can. Not only do we look for the solution to best process the end users material, but, we are mindful to provide the best value and performance in the most economical way.

Valuable Site ServiceLONGi is proud to be able to provide experienced mechanical, electrical and magnetic engineers able to assist with most any installation, commissioning or training issues that may arise.

Our main goal is to eliminate any situations before they arise at the work site both before and after the project. LONGi also has strategically located offices within easy access to current and future operating sites to provide spare parts and service and allow for minimal down time.

Ongoing Feedback ServiceLONGi is as concerned with not only the equipment we are selling tomorrow, but, with those out in the yield already. With a customer first attitude LONGi makes it a point that past sales are just as important as the future. Because of this LONGi will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.

Certificates

LONGi Laboratory introduction

LONGi Laboratory was established in 2006. It is a comprehensive mineral processing laboratory with magnetic separation gravity separation, flotation and X-ray separation. It is an important part of the magnetic separation engineering technology research center which is approved by CMIF (China Machinery Industry Federation).The laboratory covers an area of more than 4000 square meters, with a complete single magnetic separation testing machines and with a combined in any combination of magnetic separation, gravity separation, and flotation separation testing lines.

The LONGi mineral processing laboratory can conduct mineral processing research experiments, confirmatory experiments and process flow sheet design experiments, analyze the properties of the ore in combination with the experimental data, and provide optional experimental reports, and provide process flow sheet and the basis for equipment model selection.

The LONGi mineral processing Laboratory can provide mineral processing experiments and main mineral elements analysis services for domestic and foreign beneficiation plants and scientific research institutes. It also undertakes the internship tasks of undergraduate and graduate students majoring in mineral processing at China University of Mines, Northeastern University and other universities. It is a test base for high-tech mineral processing equipment and the cradle of technical talents in mineral processing in northern China.

Packing, Storage, and Transportation

Longi has plenty of cases and much experience for delivery of the heavy equipment. Some of the equipment is disassembled into pieces during shipment. The key parts like motor will be fully sealed during transportation.