Certification

Application Project

Delivery and Package

If you are interested in our drying machine products, please contact us.

Application Project

- Drying herb: pseudo-ginseng, aniseed, Chinese yam, sea cucumber, honeysuckle ect.

- Drying agriculture products: dragon fruit flower, rose, mushroom, red pepper ect.

- Drying fruit: banana, apple , mango, date, wolfberry, lemon, olive ect.

- Drying seafood: sea fish, shrimp, seaear, cuttlefish ect.

- Drying tea: puer, red tea, ect.

- Drying food: noodle, sausage, preserved pork, beancurd sticks ect.

- Drying incense: incense, mosquito incense ect,

- Drying wood: redwood, redwood furniture ect.

What is KINKAI heat pump brand fruits/vegetables/seafood/herbs etc cabinet dryer?

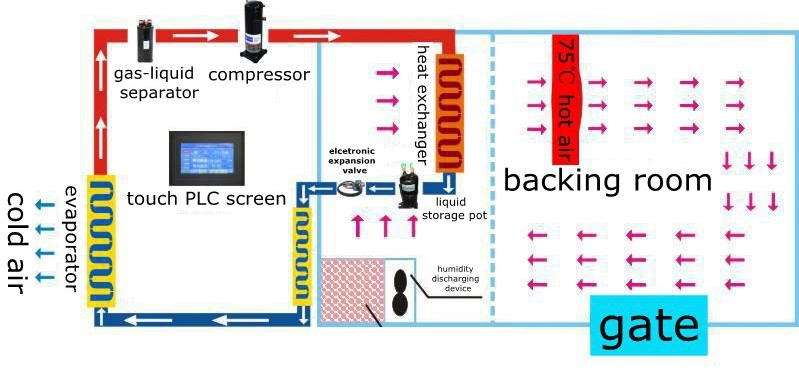

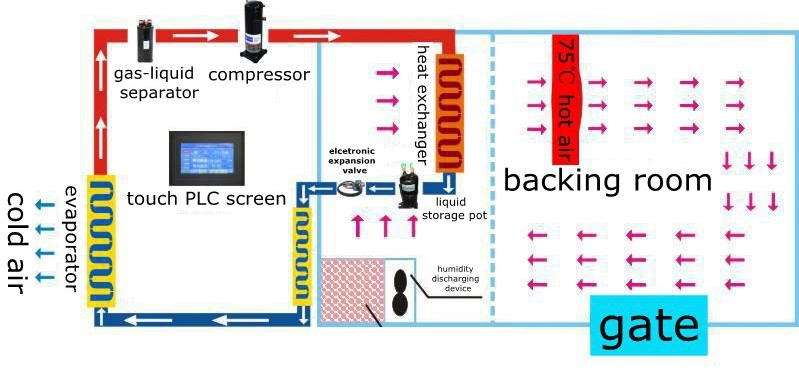

KINKAI brand heat pump dryer,infact is use of the heat pump technology applying into drying. A Heat pump dryer is the use of reverse carnot principle, absorbing outdoor hot air and transferring them into the drying room, to realize the temperature of drying room, cooperate with relevant equipment to realize the material drying.The heat pump dryer main parts including compressor, heat exchanger , choke, heat absorber - compressor unit constitute a circulation system, etc.Under the action of refrigerant in the compressor circulating in the system.It made within the compressor gas booster heating process (temperature up to 100 ºC), heat release it into the machine-- high temperature heating drying room air, while being cooled and translated into flow liquid when it runs to the outside machine, rapid heat evaporating liquid into a gas again, at the same time, the temperature dropped to minus 30 ºC, 20 ºC, the air surrounding the heat absorber will continue to transfer heat to the refrigerant.The refrigerant cycle is constantly realize heat from the air transport to the drying room heating the air inside the room temperature.

Product Principle

1, Dryer evaporator of refrigerant absorb the air from outside.

2, Then compressor works that make the air temperature rise.

3, Heat exchanger change the hot air into drying chamber.

4, Final materials will be dried by the hot air circulating in drying chamber.

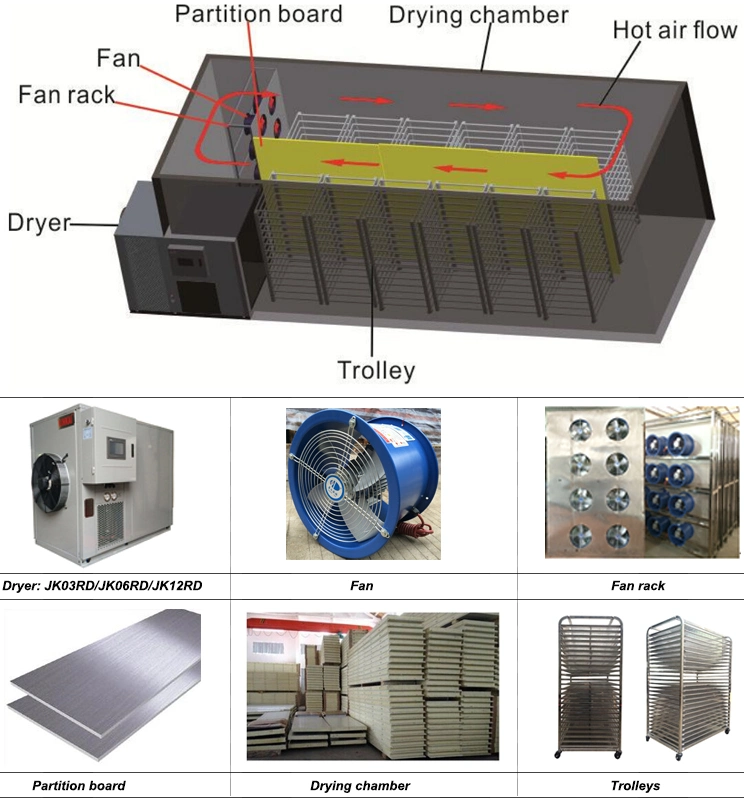

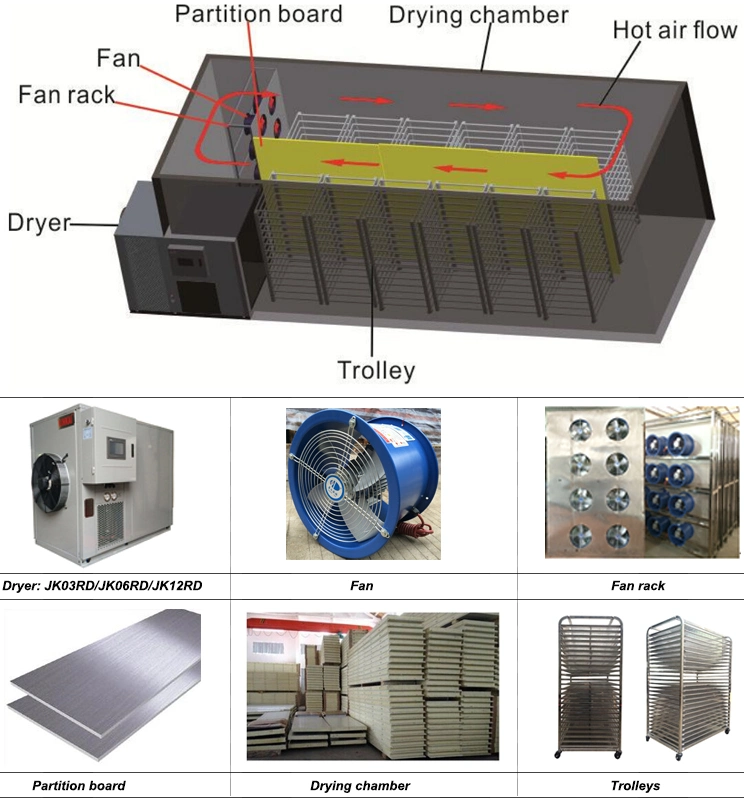

Product Component

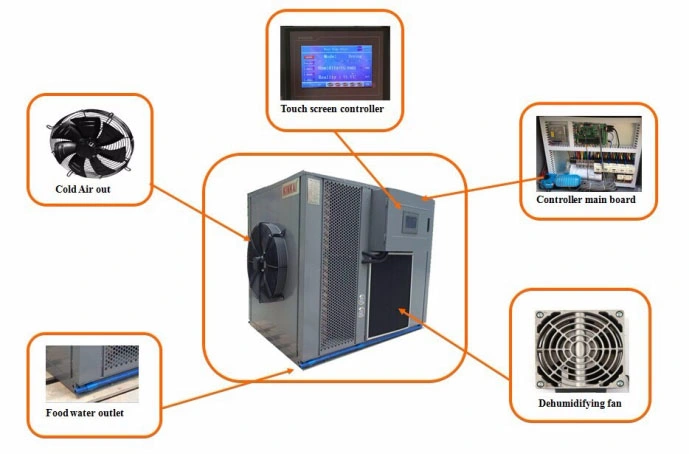

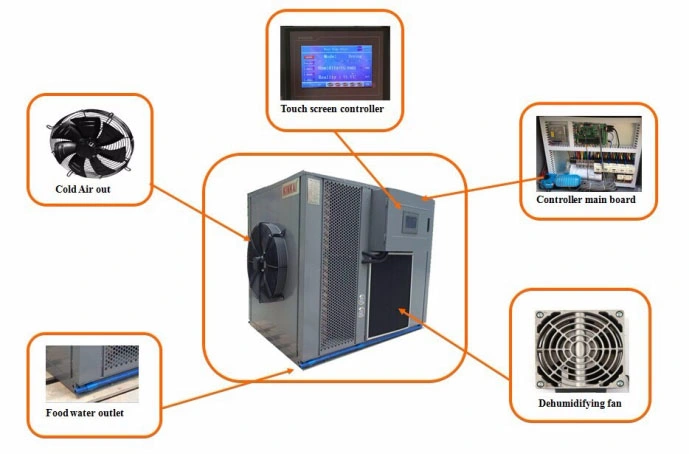

Component of Main Engine

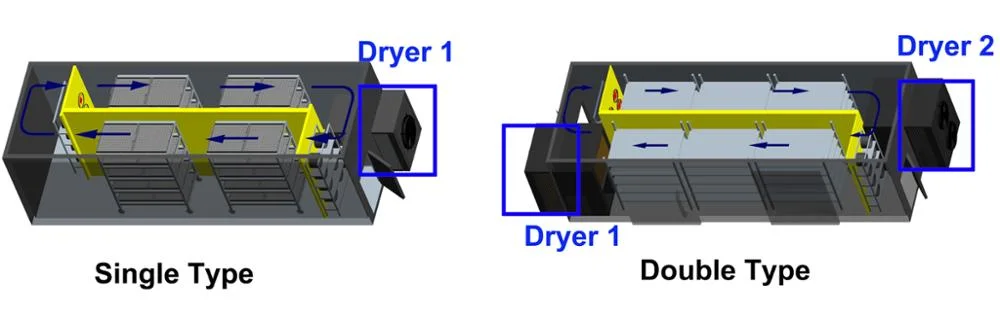

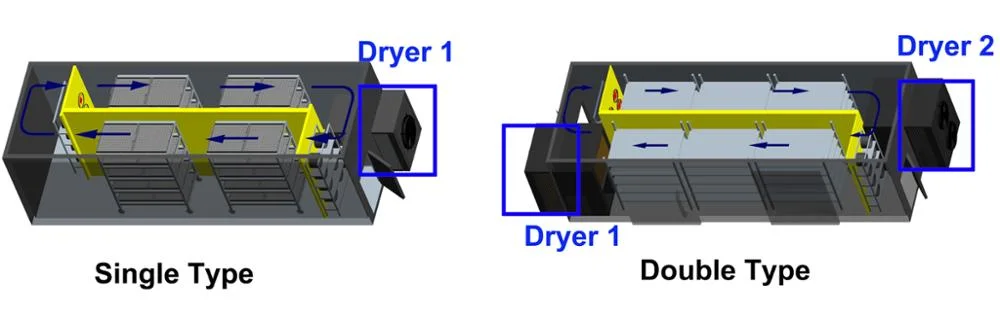

The Single Type and Double Type

Advantage of Kinkai Heat Pump Dryer

1.Energy saving & Environmental protection

Adopt close dehumidify + hot air circulating drying type, saving operating cost; Without waste gas and waste heat pollution, low noise.

2.Running Stable, operating easily

PLC + Touch Screen, running stable,operating easily; Adopt PLC control, can setting different dryiing curve, Suitable for drying different materials.

3.Second waste heat recovery technology(patent)

Adopt air to air heat exchanger dehumidify and recovery waste heat at the same time, saving energy more than 70%.

4.Exact control temperature and humidity

According to different material setting different drying curve, the heat pump dryer can control the drying chamber temperature between 10-75ºC.

5.Recovery volatilized component

Some kinds of material contain volatilized component, in drying processing, hot and wet air will become condenser water then drain, collect the condenser water so that collect volatilized component.

Technical Parameters

Product Principle

1, Dryer evaporator of refrigerant absorb the air from outside.

2, Then compressor works that make the air temperature rise.

3, Heat exchanger change the hot air into drying chamber.

4, Final materials will be dried by the hot air circulating in drying chamber.

Product Component

Component of Main Engine

The Single Type and Double Type

Advantage of Kinkai Heat Pump Dryer

1.Energy saving & Environmental protection

Adopt close dehumidify + hot air circulating drying type, saving operating cost; Without waste gas and waste heat pollution, low noise.

2.Running Stable, operating easily

PLC + Touch Screen, running stable,operating easily; Adopt PLC control, can setting different dryiing curve, Suitable for drying different materials.

3.Second waste heat recovery technology(patent)

Adopt air to air heat exchanger dehumidify and recovery waste heat at the same time, saving energy more than 70%.

4.Exact control temperature and humidity

According to different material setting different drying curve, the heat pump dryer can control the drying chamber temperature between 10-75ºC.

5.Recovery volatilized component

Some kinds of material contain volatilized component, in drying processing, hot and wet air will become condenser water then drain, collect the condenser water so that collect volatilized component.

Technical Parameters

| Single dryer + Drying chamber | ||||

| Model | Unit | JK03RD | JK06RD | JK12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| Power supply | V/PH/ HZ | 380V3PH,50/60HZ 220V/1PH,50/60HZ | 380V/3PH,50/60HZ | |

| Rated current | A | 11A(380V),25A(220V) | 19.0 | 39.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidify | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ºC | <75 | <75 | <75 |

| Working condition | ºC | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | I | I | I | |

| Max exhause pressure | Mpa | 3.0 | 3.0 | 3.0 |

| Noise | dB(A) | 75 | 75 | 75 |

| Power consumption | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING 360° | ||

| Dimension of dryer | MM | 1650x856x1280 | 1650x1056x1280 | 2250x1360x1590 |

| Weight | KG | 180 | 285 | 480 |

| Double dryer + Drying chamber | ||||

| Model | Unit | JK03RD(*2) | JK06RD(*2) | JK12RD(*2) |

| Power input | KW | 11.0 | 18.4 | 32.8 |

| Power supply | V/PH/ HZ | 380V3PH,50/60HZ 220V/1PH,50/60HZ | 380V/3PH,50/60HZ | |

| Rated current | A | 22A(380V),50A(220V) | 37.0 | 66.0 |

| Heating capacity | KW | 21.0 | 42.0 | 84.0 |

| Cooling capacity | KW | 15.6 | 36.0 | 64.0 |

| Dehumidify | L/H | 24.0 | 50.0 | 100.0 |

| Max temperature | ºC | <=75 | <=75 | <=75 |

| Working condition | ºC | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | I | I | I | |

| Max exhause pressure | Mpa | 3.0 | 3.0 | 3.0 |

| Noise | dB(A) | <=75 | <=75 | <=75 |

| Power consumption | KWH | 9.6 | 17.0 | 30.0 |

| Electric heater | KW | 6.0 | 12.0 | 24.0 |

| Blowing type | / | HORIZONTAL BLOWING 360° | ||

| Dimension of dryer | MM | 1650x856x1280 | 1650x1056x1280 | 2250x1360x1590 |

| Weight | KG | 180(*2) | 285(*2) | 480(*2) |

| Recommend Dryer + Drying Chamber Sizes | |||

| Item | Description | Product Capacity | Drying Chamber Sizes |

| 1 | One unit JK03RD dryer+drying chamber | 300KG/batch | 3160*2070*2200mm |

| 2 | One unit JK06RD dryer+drying chamber | 600KG/batch | 5700*2170*2200mm |

| 3 | One unit JK12RD dryer+drying chamber | 1200KG/batch | 5810*3230*2200mm |

| 4 | Two unit JK03RD dryer+drying chamber | 800KG/batch | 7510*2070*2200mm |

| 5 | Two unit JK06RD dryer+drying chamber | 1500KG/batch | 10530*2170*2200mm |

| 6 | Two unit JK12RD dryer+drying chamber | 3000KG/batch | 10750*3230*2200mm |

If you are interested in our drying machine products, please contact us.