How to use Ship Launching Airbags

Large Ships ~ Small Vessels ~ Dry Dock ~ Ship Salvage

Ship launching airbags are also known as inflatable marine airbags, roller bags, air lift bags, and salvage bags. Marine Airbags range in size from 0.8 to 2.5m diameter, with lengths of 5.0m to 24.0m 'effective length'. Marine Airbags are used for ship launching, haulouts, loading, and floating. They are widely used in cargo boat launching and landing, lifting and moving sunken ships, and salvaging stranded boats. Marine Rubber Air bags have the benefit of not only saving labor and time, but investment costs. Additionally they are flexible, portable, and dependable. Read More details at: http://ninglu-fishfinder.en.made-in-china.com

LAUNCH UP TO 55,000 DWT

How the Layers of Marine Air Bags are so different?

4-layer bags that are 1.5m dia x 15m long contain a rubber content that is not less than 51%. The airbags can safely hold 156-tons with a safe working pressure of 0.08MPa while rolling. When standing still the highest lifting pressure is 0.10MPa while holding 194-tons.

~~~~~~~~~~

6-layer bags that are 1.5m dia x 15m long contain a rubber content that is not less than 51%. The marine airbags can safely hold 234-tons with a safe working pressure of 0.12MPa while rolling. When standing still the highest lifting pressure is 0.14MPa while holding 272-tons.

36,000 DWT Bulk Carrier Launched by Airbags in Wuzhou Shipyard

AirbagTeam Marine offered the Ship Launching Airbags solutions for a Bulk Carrier of DWT 36,000 in Wuzhou Heavy Industry Shipyard, the Vessel is 190 meters length and 28.3 meters width, total 50pcs Airbags are offered for the Vessel's launching applications.

During the launching process, AirbagTeam Marine invited two Shipyards from South America to witness and mutually discussed the technical solutions, successfully reached the package project contract with the two Shipyards on the purchase and technical support of the airbags.

Technical Strengths:

1. Higher content Natural Rubber materials, 56%. Higher content natural rubber prove to be superior quality.

2. Gas Tightness. We design to secure the Pressure Decrease is not exceeding 5% around approximately 72 hours

3. Configuration of Airbag Layers. Layers should mean corresponding synthetic tyre cord layers and additional rubber layers combination to secure longer lifespan.

4. Breaking force of Synthetic-Tyre-Cord. Every strand is over 31kgs breaking force to reinforce the tensile strength.

The arrangements of air bags

Launching type

Based on the ship shapes, the ship may be launched, using air bags, by either end launching type or side launching type

End launching type

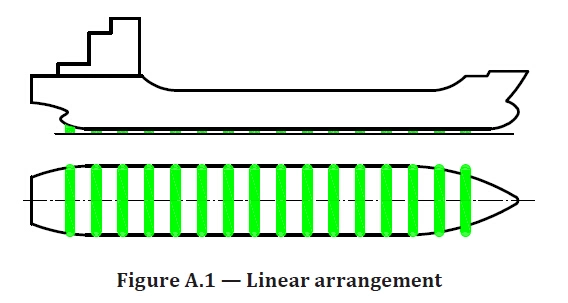

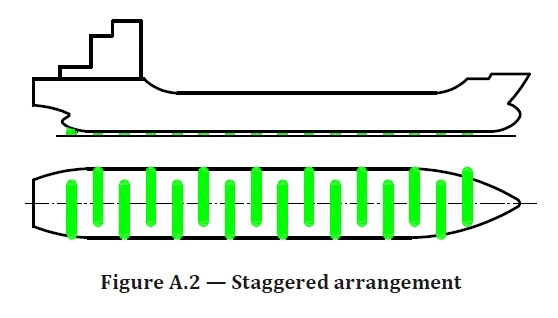

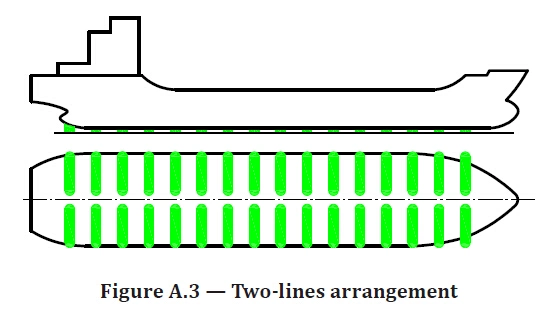

There are three ways to arrange air bags when using the end launching type. They are linear arrangement (see Figure A.1), staggered arrangement (see Figure A.2), and two-lines arrangement (see Figure A.3). As for which arrangement to use, it will depend on the ship's width and the length of the air bags.

1. When the ship's width is not greater than the effective length of the air bags, the linear arrangement shall be selected.

2. When the ship's width is greater than the effective length of an air bag and less than the effective length of two air bags, the staggered arrangement can be selected.

3. When the ship's width is greater than the effective length of an air bag and less than the effective length of two air bags, the staggered arrangement can be selected.

Towing arrangement

A windlass shall be used to control the movement of the ship. Tow system that comprises windlass, steel wire rope and pulley set shall be securely fastened to the ground anchor in front of the berth.

In general, a slow windlass shall be selected for ship launching. The veering speed of the windlass shall be 9 m/min to 13 m/min.

The forces of the windlass and the steel wire rope should be calculated carefully by technicians of ship yards or air bags company.

For price quotes - please answer the following questions:

1. Type of vessel?

2. LOA (length) of ship?

3. Width of vessel?

4. Vessel's actual launched weight (gravity weight)/weight without cargo?

5. What is the vessel's DWT?

6. Type of ground ship is built on? (Dirt, concrete, etc.)

7. Depth in meters of the water where the ship first enters the water?

8. What's the angle degree of slipway? (Land, not under water)

9. Please provide the low/high tide schedule at site.

10. The working height? (The block stand height under the vessel)

11. Distance from bottom of propeller to the water level?

12. Distance from back of vessel (in dry dock) to the water entry point?

NEED HELP? CALL OUR AWARD-WINNING SUPPORT TEAM 24/7 AT

+86 135 8920 6919

Mob: +86 135 8920 6919