Insulating glass 3A molecular sieve introduction:1.Main features

3. Main uses:

1. Adsorb water and organic residues in the insulating glass simultaneously

2. Keep and stabilize dew point of insulating glass

3. Don't adsorb sulfur hexafluoride

4. Packaging details:

1.150kg/55gallon air-tight iron drum and each drum han inner PE bag.

2.25kg carton and each carton has inner PE bag.

3.Packaging according to your requirement.

4.All of these packing can withstand the long-distance shipping.

Package:

25kg per carton F50x31x20cm

25 kg steel barrel D32x48cm

12000kgs per 20 feet container.

Molecular Sieve 3A for Insulating Glass,Desiccant Dryer,Molecular sieve dryer

Molecular Sieve (Desiccant) 3A and 4A

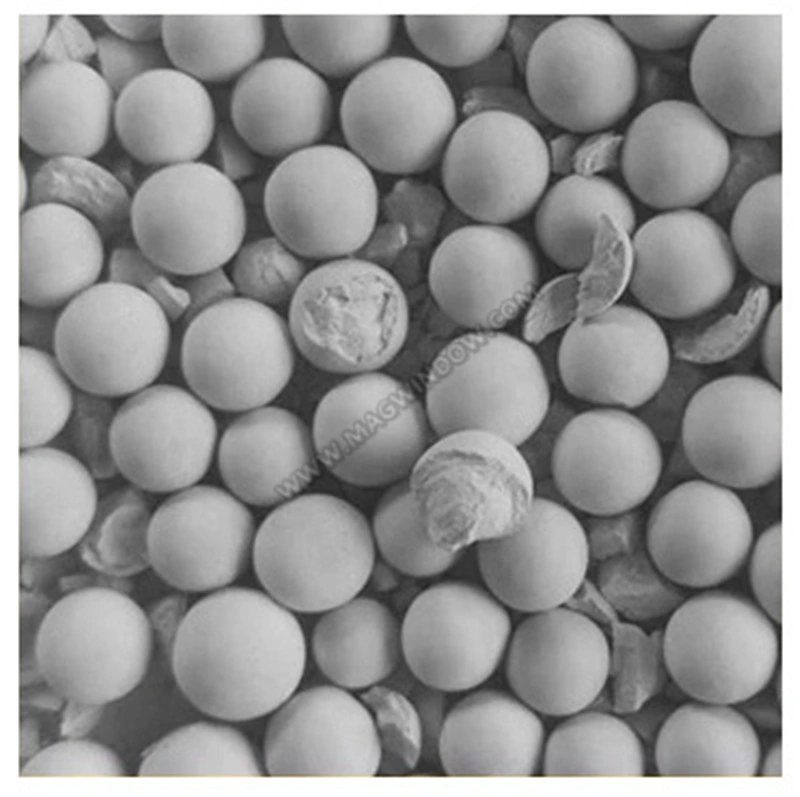

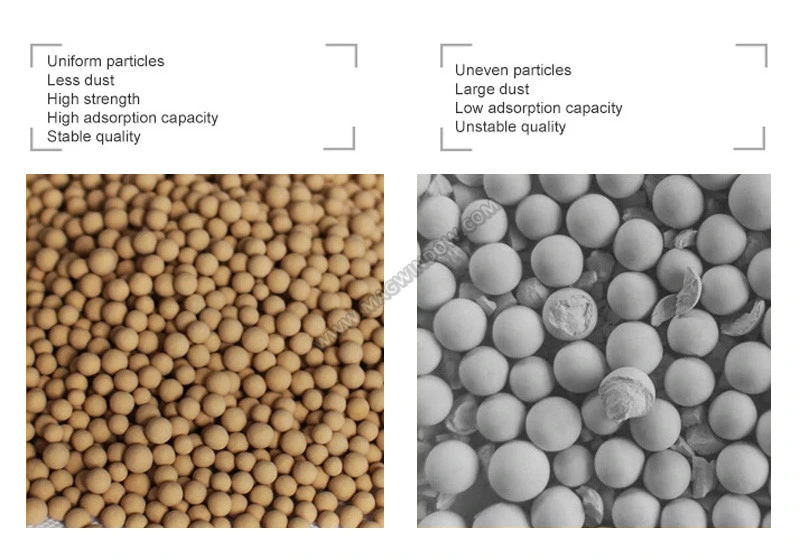

Insulating glass molecular sieve is made from zeolite and clay mineral. It is featured with porous solid structure and light yellow/white ball particles

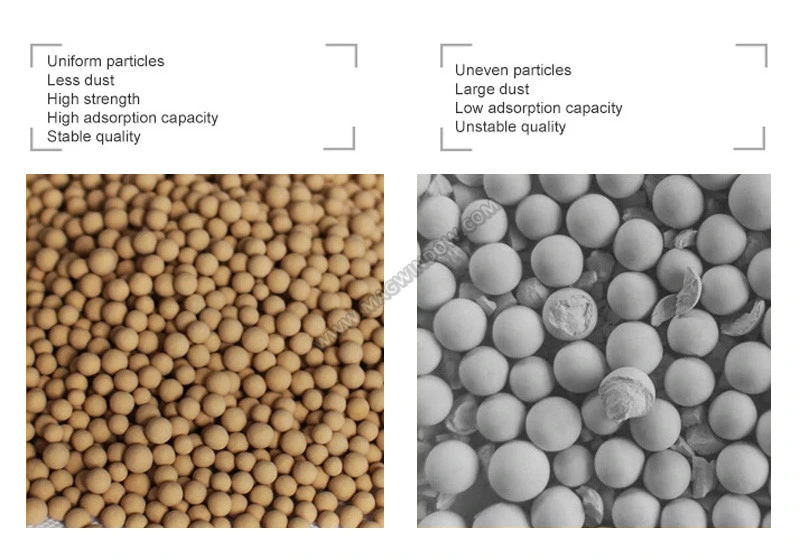

Features:

1). High hardness, smooth surface, high abrasion resistance, no peeling, no break.

2). Absorb moisture only.

3).Good temperature stability

Note:

1). In filling process, try to shorten the time of molecular sieve in the air;

2). If you open the package for 70 minutes and make the molecular sieve exposed to the air all the way, it will lose activity.

Storage:

For steel barrel, the storage time can reach 5 years; for carton, the storage time should be only 18 months

- .Insulating glass molecular sieve can co-adsorb the resident moisture and organics in insulating glass,keep the insulating glass clear and transparent even at very low temperature.

- .In the mealtime it can successfully avoid the tremendous air pressure difference placed on the glass,which was caused by great change of temperature because of the seasonal variation and day-night transformation,thus it resolves the problems of windows distortion by insulating glass inflation and shrink,expanded the life of insulating glass windows.

| Item | Unit | Bead | Test condition | ||

| Diameter | mm | 0.5-0.85 | 1.0-1.5 | 1.5-2.0 | |

| Static water adsorption | ≥%wt | 18 | 18 | 18 | RH10%,25°C |

| Bulk density | ≥g/ml | 0.75 | 0.75 | 0.75 | Settled |

| Loss on Ignition | ≤%wt | 1.50 | 1.50 | 1.50 | 950°C |

| Delta temperature | ≥°C | 40 | 40 | 40 | 10g/10mlH2O,25°C |

| Gas desorption | ≤Ml | 50 | 50 | 50 | 250ml,70°C |

| Partical ratio | ≥% | 98 | 98 | 98 | National standard 95 |

| Water content,as shipped | ≤%wt | 1.5 | 1.5 | 1.5 | |

1. Adsorb water and organic residues in the insulating glass simultaneously

2. Keep and stabilize dew point of insulating glass

3. Don't adsorb sulfur hexafluoride

4. Packaging details:

1.150kg/55gallon air-tight iron drum and each drum han inner PE bag.

2.25kg carton and each carton has inner PE bag.

3.Packaging according to your requirement.

4.All of these packing can withstand the long-distance shipping.

Package:

25kg per carton F50x31x20cm

25 kg steel barrel D32x48cm

12000kgs per 20 feet container.

Molecular Sieve 3A for Insulating Glass,Desiccant Dryer,Molecular sieve dryer

Molecular Sieve (Desiccant) 3A and 4A

Insulating glass molecular sieve is made from zeolite and clay mineral. It is featured with porous solid structure and light yellow/white ball particles

Features:

1). High hardness, smooth surface, high abrasion resistance, no peeling, no break.

2). Absorb moisture only.

3).Good temperature stability

| Item | Value |

| Particle size range | 0.6-0.85mm 1.0-1.5mm 1.5-2.0mm 2.0-2.5mm |

| Dust content | Max 30ppm |

| Compressive strength | 5N, 15N, 25N, 30N |

| Bulk density | 0.70-0.75kg/L |

| Temperature rise | min 40ºC |

| Air adsorption capacity | max 50ml |

| Nitrogen adsorption ability | max 0.2% |

| Sieve rate | min 95 wt.% |

| Saturated adsorption ability in 25ºC | 20% r.h min. 17.0wt.% |

| 50% r.h min. 20.0wt.% | |

| 90% r.h min. 20.5wt.% |

Note:

1). In filling process, try to shorten the time of molecular sieve in the air;

2). If you open the package for 70 minutes and make the molecular sieve exposed to the air all the way, it will lose activity.

Storage:

For steel barrel, the storage time can reach 5 years; for carton, the storage time should be only 18 months