FGD Pump Introduction:

TL(R) flue gas desulfurization(FGD) pump is single stage, single suction horizontal centrifugal pump, specially

designed to meet the requirements of wet process FGD of limestone(lime) and gypsum for coal fired power

plants. We have elaborately developed a new material which possesses anti-corrosion of duplex stainless steel

and the anti-abrasion of high chrome white iron, making sure the durable use and stable working performance.

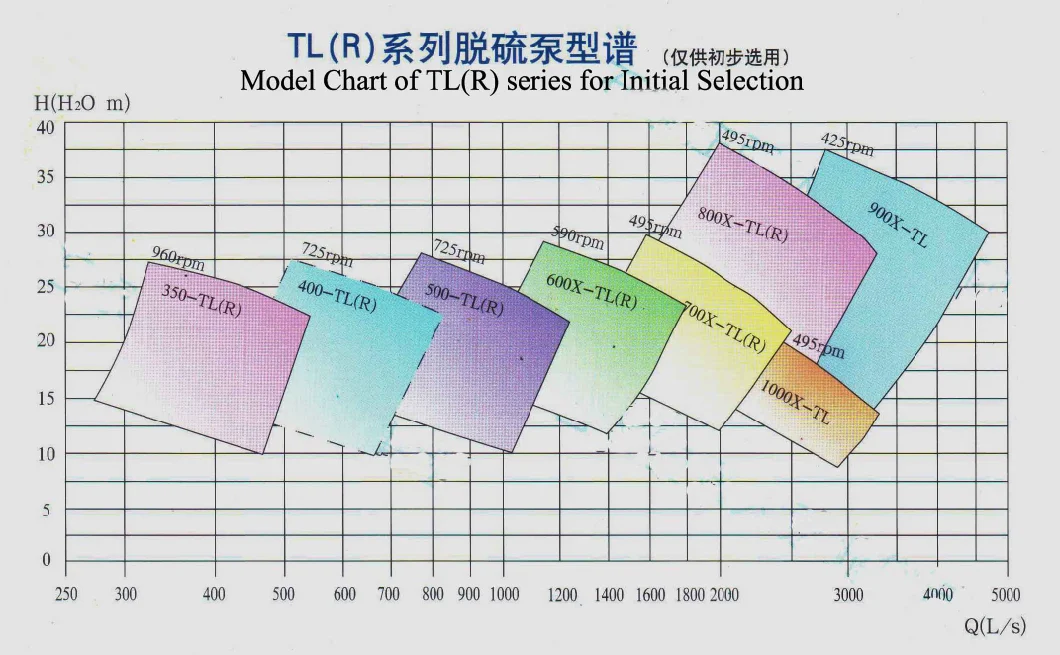

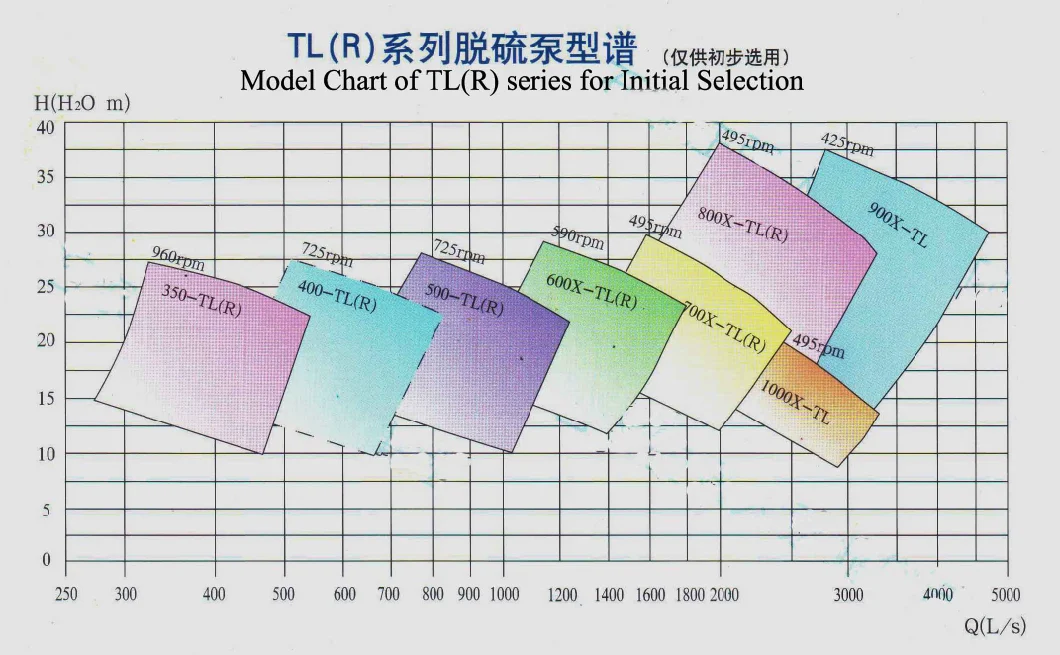

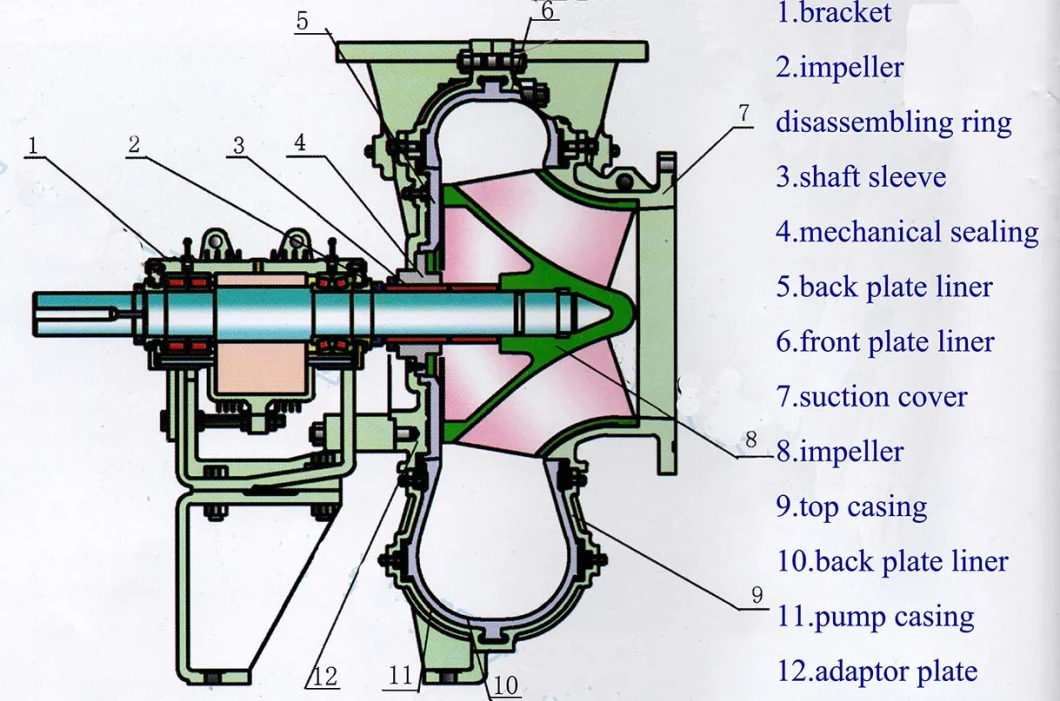

Pump Section Chart for FGD pump

Features:

1. The wearing parts adopted with CFD (Computational Fluid Dynamics) so as to designed reliability and high efficiency.

2. The position of the impeller can be changed by adjusting bearing assembly and the pump Unit can be in efficiency operation state.

3. Pump is back disassembly type and needn't dismantle the pipe connection so as to ensure Structure is simple and easy to maintain.

4. Pump head use double rows taper roller bearings and drive end use cylindrical roller bearings, Bearings are lubricated with recycled dilute oil, improved the bearing working condition and Increased service life.

5. Mechanical seal adopted with containers type mechanical seal to ensure reliable running.

6. It is easy to maintain and repair and it is on need dismantling inlet and outlet water pipes.

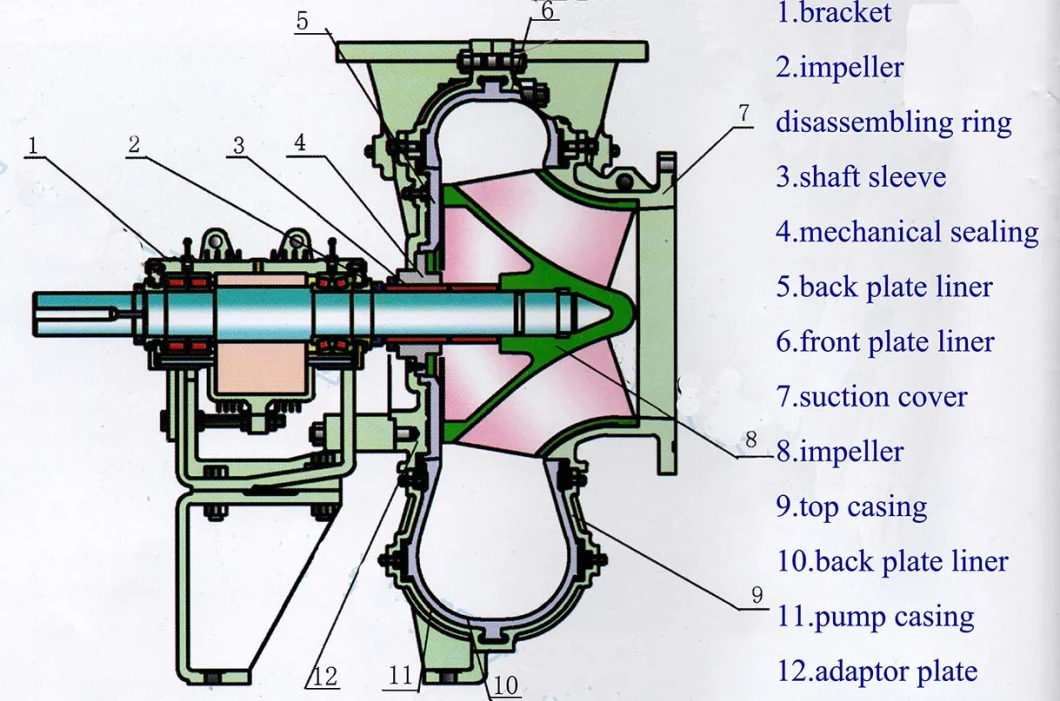

Structure:

Applications and Characteristics:

The pump restricting parts adopt the advanced flow simulation technology to guarantee the reliable pump design and the high operating efficiency. The anti-corrosion & anti-wear metal and rubber materials which are specifically developed for FGD pumps have been proved by the practice that they can ensure the long-life pump operation. Through adjusting the bearing components to change the impeller position in the pump chamber all-time high-efficient operation of the pump can be achieved. The pump is characterized by the back knock-down structure which is simple and advanced. It is easy to maintain and repair and it is on need dismantling inlet and outlet water pipes. The containerized mechanical seal specially used for the desulphurization process is adopted and its operation is reliable.

Welcome to contact us any time for details.

Your inquiry will get our prompt attention and response !

TL(R) flue gas desulfurization(FGD) pump is single stage, single suction horizontal centrifugal pump, specially

designed to meet the requirements of wet process FGD of limestone(lime) and gypsum for coal fired power

plants. We have elaborately developed a new material which possesses anti-corrosion of duplex stainless steel

and the anti-abrasion of high chrome white iron, making sure the durable use and stable working performance.

- Discharge: 350~1000 mm

- Capacity:1600m3/h-15000m3/h (444L/S-4167L/S)

- Head:15m-31m

- Speed:n=420~980rpm

- S.g.:γ ≤1.5

- Temperature:T=0~120ºC

- Working Efficiency: max to 90%

- Materials: anti-wear and corrosion-resistance

Pump Section Chart for FGD pump

| Model | Capacity | Head | Speed | Efficiency | NPSHr | Suction /Discharge Size | |

| M3/hr | L/s | M | R/min | % | mm/mm | ||

| 350TL(R) | 1600 | 444 | 25 | 960 | 82 | 4.5 | 350/400 |

| 400TL(R) | 2500 | 694 | 25 | 725 | 83 | 5.0 | 400/450 |

| 500TL(R) | 3750 | 1040 | 25 | 725 | 85 | 5.0 | 500/500 |

| 600TL(R) | 6300 | 1750 | 25.5 | 620 | 88 | 5.5 | 600/700 |

| 700TL(R) | 6840 | 1900 | 26 | 485 | 87 | 6.0 | 700/800 |

| 800TL(R) | 9360 | 2600 | 31 | 485 | 90 | 7.0 | 800/900 |

| 900TL(R) | 15000 | 4167 | 30 | 485 | 90 | 8.5 | 900/1000 |

| 1000TL(R) | 10440 | 2900 | 15 | 485 | 89 | 7.0 | 1000/1200 |

Features:

1. The wearing parts adopted with CFD (Computational Fluid Dynamics) so as to designed reliability and high efficiency.

2. The position of the impeller can be changed by adjusting bearing assembly and the pump Unit can be in efficiency operation state.

3. Pump is back disassembly type and needn't dismantle the pipe connection so as to ensure Structure is simple and easy to maintain.

4. Pump head use double rows taper roller bearings and drive end use cylindrical roller bearings, Bearings are lubricated with recycled dilute oil, improved the bearing working condition and Increased service life.

5. Mechanical seal adopted with containers type mechanical seal to ensure reliable running.

6. It is easy to maintain and repair and it is on need dismantling inlet and outlet water pipes.

Structure:

- Cartridge mechanical seal with internal or external flushing plans, single seal and double seal are both available.

- All metal materials for pump set, without any lining rubber or other high polymer material.

- Pump casing adopts duplex stainless steel of 2605N and 2205,which have excellent resistant performance of chloride ions and sulfate ions,and therefore is the first choice of desulfurization pumps.

- Front and back open structure,the rotary part can be removed from the casing without dismantling the pipelines.

- The bearing part is back pull structure,which is assembled in the bearing housing.

- Transmission: directly coupled and gear box drive.

Applications and Characteristics:

The pump restricting parts adopt the advanced flow simulation technology to guarantee the reliable pump design and the high operating efficiency. The anti-corrosion & anti-wear metal and rubber materials which are specifically developed for FGD pumps have been proved by the practice that they can ensure the long-life pump operation. Through adjusting the bearing components to change the impeller position in the pump chamber all-time high-efficient operation of the pump can be achieved. The pump is characterized by the back knock-down structure which is simple and advanced. It is easy to maintain and repair and it is on need dismantling inlet and outlet water pipes. The containerized mechanical seal specially used for the desulphurization process is adopted and its operation is reliable.

Welcome to contact us any time for details.

Your inquiry will get our prompt attention and response !